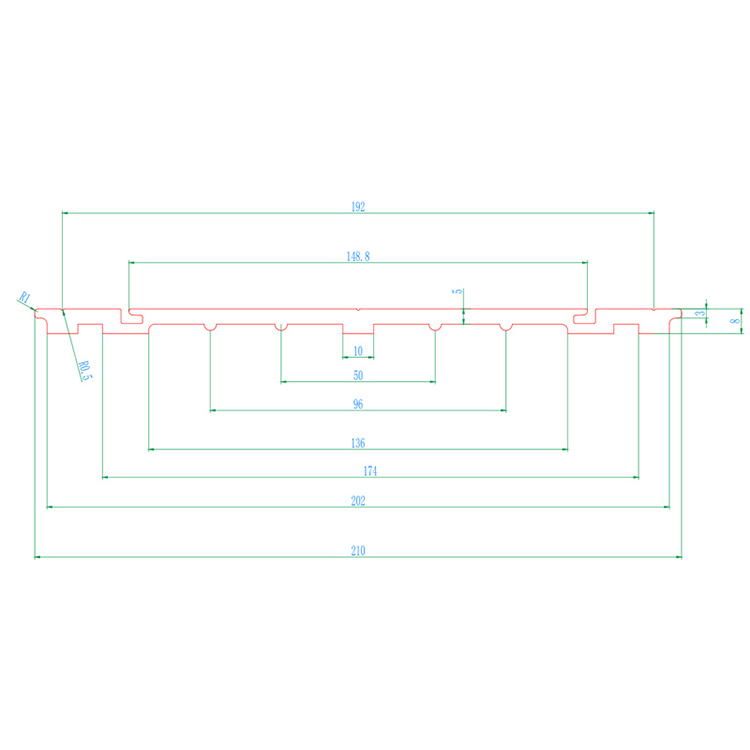

Aluminium extrusion profile tloaelo No GKX-Y1489

Lintlha tsa Sehlahisoa

LIEKETSENG TS'OANELO

6063-T5 Kapa Joalo ka Tlhokahalo

LITŠOANTŠISO

Welding = E babatsehang

Ho sebetsa/ Ho sila = Ho kgabane

Ho kobeha / Ho theha = Ho hotle

Apara Resistance = E babatsehang

Corrosion Resistance = E babatsehang

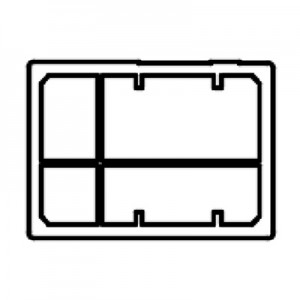

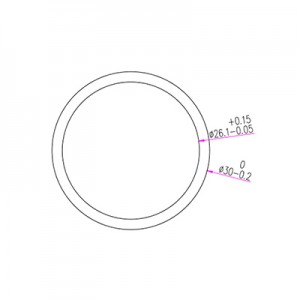

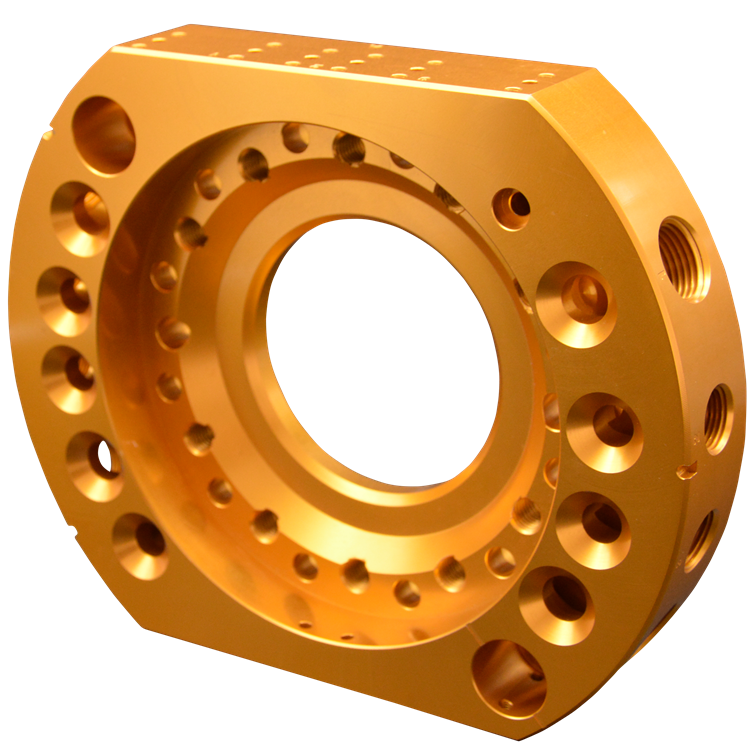

Karolo e fapaneng kapa Mohlala oa Sebele

E phahameng litlhoko tsa mamello ea boemo ba profil, ho thata le ho feta, li-cavities tse ngata ka har'a profil, , joale mookameli oa lefu o bonolo ho otloa nakong ea extrusion.Botenya ba lebota ba profil bo tla fapana bakeng sa boholo bo fapaneng ba li-extruder le litlhophiso tsa profil

Aluminium alloy limaraka

Limaraka tsa alloy ea aluminium tse ngolisitsoeng machabeng

Ho na le ba fetang 1 000, ho tloha ho 1 000 ho ea ho 8 000

Sehlopha se seng le se seng se na le tse 'maloa Mophato o mong le o mong o na le linaha tse ngata, ho latela boima, matla, ho hanyetsa kutu, ts'ebetso ea ts'ebetso, weldability, thepa e khabisitsoeng ea phapang.

Phekolo ea Bokaholimo

Kalafo e sebelisoang ka mokhoa o tloaelehileng ea aluminium e na le "spray coating, sandblasting, electrophoresis, oxidation, silika e hulang, lijo-thollo tsa lehong, ho polishing lik'hemik'hale, PTFE, joalo-joalo.

Litlhoko tsa ho Qetella

Aluminium extrusion molding ho phaella ho phekolo ea holim'a metsi, re ka boela ra hlahisa tse ling tsa morao-rao, tse kang ho itšeha, ho phunya, ho khumama, joalo-joalo.

Mokhoa o ikhethileng oa ho bula hlobo

Mokhoa o ikhethileng oa ho bula hlobo

Litlhoko tse bulehileng tsa ho etsa hlobo:

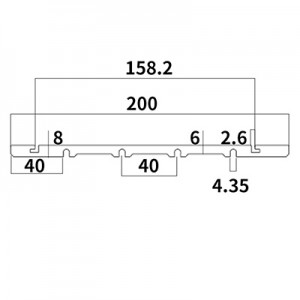

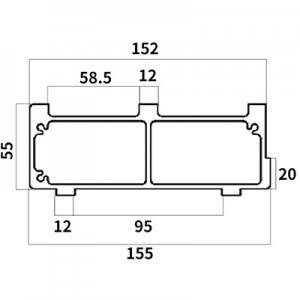

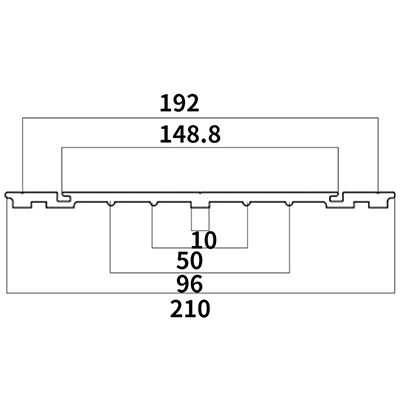

1, Metako ea boholo Metako ea boholo (CAD kapa sebopeho sa 3-dimensional, sebopeho se bonolo se ke ke sa hloka litšoantšo)

2. Mehlala ea 'mele

Taolo ea Boleng

1. Mekhoa ea tsamaiso ea boleng e tiisitsoeng

Lisebelisoa tsa 7.Measuring le lisebelisoa tsa teko

2. Tlhahlobo e kenang ea thepa e tala le lihlahisoa tse tsoang kantle, ka lirekoto tsa tlhahlobo ea karolo ea pele.

3.E-ba le tlhahlobo ea ts'ebetso, lihora tse 2 ka nako

4.Tlhahlobo ea thomello

5. Etsa thepa e kenang, sampole ea pele, tlhahlobo ea tšebetso le thomello ho latela litaelo tsa mosebetsi oa tlhahlobo.

6. Ho ba le sekgahla sa ho pasa le sekgahla se senyehileng sa boleng ba tlaleho ya kgwedi le kgwedi

7. Lisebelisoa tsa ho lekanya le lisebelisoa tsa tlhahlobo

8. Litaelo tsa mosebetsi oa tlhahiso ea tlhahiso

9. Moralo le tlhahiso ea hlobo le li-jigs le lisebelisoa.

Tšebeletso ea Lefatše